Lotus Engineering, the engineering consultancy division of Group Lotus plc, has been

awarded a major industry award for its innovative and technologically leading Versatile Vehicle

Architecture (VVA).

Lotus Engineering won the European Aluminium Award 2006 in the "Transport and

Automotive" category held at "Aluminium 2006" - 6th World Trade Fair and Conference in

Essen, Germany.

At "Aluminium 2006", Versatile Vehicle Architecture technology was demonstrated by the "APX

by Lotus Engineering" prototype vehicle that was first shown to the world at the Geneva

Motorshow earlier this year. The APX (Aluminium Performance Crossover) is the first example

of a complete vehicle built on the innovative Versatile Vehicle Architecture (VVA) – the first

Lotus production car using this technology will be the new Lotus Esprit flagship sports car to

enter production in December 2009.

The innovative VVA technology offers a fast-to-market, cost-effective approach to

differentiated niche products by spreading the development, investment and bill of materials

burden across a range of niche vehicle variants, without the compromise that stems from

conventional 'platform sharing'. The key to the VVA architecture is the extensive use of

Aluminium in the form of high-pressure die cast corner nodes that are combined with extruded

and pressed aluminium via bonding and mechanical fasteners.

The European Aluminium Awards Jury recognised that Lotus used its knowledge in lightweight

materials, such as Aluminium, to its advantage to build the APX, and that Lotus satisfied the

Jury's key criteria of originality, functionality, design, durability and recyclability.

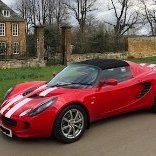

Lotus won this award back in 1996 for the Lotus Elise chassis - at the time a ground-breaking

and innovative technology itself.

More about the European Aluminium Awards

The European Aluminium Awards (EAA) are organised by the EAA , the Gesamtverbandes der

Aluminiumindustrie (GDA)., the Dutch Aluminium Centrum, and "Aluminium 2006" - 6th World Trade Fair and

Conference and supported by global players of the aluminium industry : Alcan, Alcoa, Corus and Hydro

Categories of the European Aluminium Award 2006

"Aluminium End Product Award", aimed at the customers of aluminium and presents three prizes for

· Design

· Innovation

· Environment & Sustainability

"Industrial Innovations Award" aimed at the three main application areas of aluminium:

· Transport & Automotive

· Building & Construction

· Machinery & Electronics

The jury consisted of:

· Prof. Laurens Katgerman, Technical University Delft, Netherlands (Chairman)

· Ms. Roberta Bordiga, Editorial staff Edimet, Aluminio e Leghe Italy

· Mr Eur.Ing. Steve Harmer BSc, The Institute of Materials, UK

· Mr Elmar Schueller, Vice-President Red Dot, Germany

· Mr Rein van de Velde, Aluminium Centrum, Netherlands (secretary)

The jury, in the assessment of the entries took the following criteria into account:

· a) Originality and functionality of the use of the materials; he degree to which the metal aluminium is

used in an original and useful manner.

· ![]() Functionality of the product; the degree to which the part meets both its primary user function and

Functionality of the product; the degree to which the part meets both its primary user function and

and its technological function. The functional combination of the use of materials, construction and

ergonomic adjustments

· c) Design; the degree to which the total design reaches a harmonic unity or a solution. In particular

the construction and assembly of the designed product and the details of the shape, all this in

relation to the material used.

· d) Durability; in relation to the life cycle costs.

· e)Recycling; the possibility to recycle the applied materials.

· f) Representational and promotional value for aluminium.

More about Lotus Versatile Vehicle Architecture (VVA) and the APX by Lotus Engineering

Lotus Versatile Vehicle Architecture (VVA) has been developed to bridge a gap in the investment-volume

curve to exploit the benefits of producing at medium volumes but for niche markets, thereby giving the best

chance of business case success and favourable returns.

The philosophy of VVA is based on the commonality and versatility of key elements of the vehicle structure

and body systems across a 'family' of niche vehicle variants, with a combined annual production rate of up to

around 50,000 units. Structural components common to each family member are arranged in different

configurations in each variant around the ingenious corner nodes.

The great advantage of this technology is that it can be used by one OEM looking to develop a range of niche

products, or by a group of OEMs looking to share investment, but still retain a high degree of end product

separation.

APX is a demonstration of Lotus Engineering's ability to create innovative and exciting, high performance

products through its world class capability in Vehicle Design, Performance Powertrain Engineering and niche

vehicle development, the first production car from this technology will be the new Lotus Esprit flagship sports

car to enter production in December 2009.

It is a 7-seater (in reality a 5 + 2 with the two rear seats being occasional) four-wheel drive "Crossover"

vehicle with a front mounted 300 hp supercharged V6 petrol engine. Weighing in at just 1570 kg and with a

power to weight ratio of 191 hp per tonne, the APX has sportscar like performance of 5.4 seconds to 100

km/h (5.0 seconds to 60 mph) before reaching a top speed of 245 km/h (152 mph). These performance

figures are as good as the highest performing 4x4 "Crossover" vehicles from other brands with up to 195 hp

per tonne. Crucially though, whereas those vehicles need higher output engines to compensate for heavy

weight, APX does not. Combined fuel consumption for APX is estimated to be 8.7 litres / 100 km (or 32 mpg)

– impressive on its own and more so when compared to its production rivals which often consume more than

13 litres per 100 km (22 mpg).

APX is manufactured predominantly from aluminium in the form of high-pressure die-cast corner nodes,

stampings and extrusions. It uses advanced assembly techniques, including adhesive bonding, self-piercing

rivets and flow-drill screws for construction – joining techniques that Lotus calls Riv-Bonding. Lotus has

optimised the use of these technologies thus significantly reducing the number of mechanical fixings within

the monocoque structure. This has reduced the level of investment required in manufacturing equipment.

Example VVA families

The following represents illustrative VVA families that could be achieved:

Family A

· Front engine 4WD crossover 15,000 / year

· Mid engine RWD supercar 5,000

· Front engine RWD coupe 10,000

· Front engine RWD saloon 20,000

Family B

· Front engine FWD coupe 10,000

· Front engine 4WD SUV 25,000

Family C

· Mid engine RWD coupe 5,000

· Front engine FWD saloon 25,000

· Front engine 4WD crossover 30,000 – i.e. APX by Lotus Engineering

About Lotus Engineering

The main operating subsidiary of Group Lotus plc is Lotus Cars Ltd, which has two operating divisions –

Lotus Engineering and Lotus Cars.

Lotus Engineering is an internationally recognised automotive engineering consultancy based in Norfolk, UK.

Its global facilities include those in Michigan, USA and Kuala Lumpur, Malaysia, and offices in Germany and

China. Lotus Engineering provides comprehensive and versatile consultancy services to many of the world's

OEMs and Tier 1 suppliers, offering a full engineering service from initial concept and project design through

development to full production. This includes 3rd party "niche vehicle" engineering and manufacture

worldwide.

Lotus Cars builds and sells Lotus sports cars, Elise, Exige and Europa; and manufactures the advanced

composite front and rear crash structures for the Aston Martin V12 Vanquish.

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.