Lotus Researches Cars Running On CO2

Exige 270E Tri-fuel is the next stage of Lotus Engineering's long-term

sustainable, synthetic alcohol research

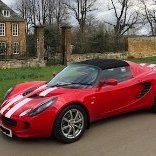

Lotus Engineering, the world renowned automotive consultancy division of Lotus, unveils its latest

development towards carbon neutral road transport at the 78th Geneva International Motor Show. The

Lotus Exige 270E Tri-fuel is the most powerful road version yet of the Exige (0-60 mph / 96 kph in 3.88

seconds, a top speed of 158 mph (255 km/h), 270 hp (201 kW / 273 PS at 8000 rpm) and it runs on any

mixture of gasoline, bioethanol and methanol. Emerging technologies will allow alcohol fuels such as

methanol, already a proven internal combustion fuel, to be made synthetically from CO2 extracted from

the atmosphere.

An alcohol-based fuel derived renewably from atmospheric CO2 would allow society to transfer relatively

easily to sustainable, carbon-neutral internal combustion. Lotus Engineering is researching the use of

sustainable synthetic alcohols as potential future fuels, with technology available from Lotus for

introduction in four to five years. However, the supply infrastructure investment from governments and

fuel companies could take 15 to 20 years.

The Exige 270E Tri-fuel is part of Lotus' research to understand the complex combustion process

involved in running on mixtures of alcohol fuels and gasoline, which will be important for a successful

transition from today's fuels to the sustainable, synthetic fuels of the future.

This research is just one aspect of Lotus Engineering's ground-breaking work on environmentallyfriendly

vehicles. It is involved with a number of electric vehicle projects, has successfully integrated

hybrid technologies into vehicles such as its EVE demonstrator, and recently announced results on a

collaboration with Continental Division Powertrain on the Low CO2 downsized three-cylinder engine.

The research into sustainable alcohols is progressing at Lotus' Hethel headquarters in Norfolk, UK and

involves input from the Royal Society of Chemistry's Alternative Fuel Symposium Series, the Low

Carbon Vehicles Innovation Platform, developed by the Technology Strategy Board and direct

discussions with the University of Sheffield.

Methanol (CH3OH) can be produced synthetically from CO2 and hydrogen. Ultimately, emerging

processes to recover atmospheric CO2 will provide the required carbon that can entirely balance the

CO2 emissions at the tailpipe that result from the internal combustion of synthetic methanol. The result

is that a car running on synthetic methanol, such as the Exige 270E Tri-fuel would be environmentally

neutral.

As well as being green, the great benefit of synthetic methanol is that it would use similar engines and

fuel systems to those in current cars; and synthetic methanol can be stored, transported and retailed in

much the same way as today's liquid fuels such as gasoline and diesel.

Synthetic methanol also possesses properties better suited to internal combustion than today's liquid

fuels, giving improved performance and thermal efficiencies. And it is ideal for pressure-charging

(turbocharging and supercharging) already being introduced by manufacturers to downsize engines in a

bid to improve fuel consumption.

Lotus Engineering's Lotus Exige 270E Tri-fuel technology demonstrator illustrates how easy it is for

synthetic methanol to be embraced over time as a future fuel for road transport. The Exige 270E Trifuel,

with its supercharged 2ZZ-GE VVTL-i engine, could be the forefather of a new generation of

conventionally driven cars that have the potential to be environmentally-neutral.

Mike Kimberley, Chief Executive Officer of Group Lotus plc, explains: "Lotus is a world-class leader in

research into a variety of alternative fuels; each has its merits and challenges and some options could

be more easily implemented than others. But while motorists want to be green, we do not want to

change the culture of total freedom for the owners, who will have an extreme reluctance to spend more

at the pump, or to sacrifice the performance of their cars.

Mike Kimberley continues, "At present, the motor industry is seeking a route to reduce CO2 emissions

just at the tailpipe; this focus is far too narrow. A sustainable alcohol such as synthetic methanol has the

potential to reduce the overall CO2 footprint of internal combustion vehicles towards zero. Produced

through CO2 recovered from the atmosphere and given a tax incentive, it immediately becomes a green,

cheap and more desirable fuel. For those compelling reasons motorists, legislators and car

manufacturers must switch to a sustainable alcohol like synthetic methanol."

Geraint Castleton-White, Head of Powertrain at Lotus Engineering explains: "For car companies and the

motorist, the use of sustainable alcohols like synthetic methanol requires relatively few changes to the

vehicle. It can also use the current fuel distribution infrastructure, which is a huge advantage for

suppliers.

Geraint Castleton-White continues, "We believe that, technically, there are a small number of significant

but by no means insurmountable hurdles to the adoption of synthetic methanol as the staple future fuel

for internal combustion. We are some way into a number of extensive research projects but of course,

we understand that further research needs to be undertaken to fully overcome potential challenges that

may arise."

David Bott, Director of Innovation Platforms within the Technology Strategy Board in the UK says: "The

approach taken by Lotus Engineering is a good balance between the desire for the lowest carbon

emissions and the practicality of car evolution. The drive for low carbon transport is a real imperative

and its progress will require short, medium and long term solutions."

Tony Ryan, ICI Professor of Physical Chemistry at the Department of Chemistry at The University of

Sheffield says: "There is a great opportunity to develop methanol as a transport fuel in a mixed energy

economy that embraces a wide range of primary energy sources, including nuclear, solar, and other

renewable power sources. Combining atmospheric CO2 with hydrogen to form methanol provides a

pathway to personal transport with low carbon emissions that uses the existing liquid-fuel infrastructure

and Lotus Engineering offers world leadership in the development of engines to use these fuels of the

future."

More detail >>>

Synthetic methanol – a green fuel?

Synthetic methanol's green credentials arise from its potential to be completely CO2 neutral. The most

likely future mass-production of the fuel is by using electrochemical techniques to combine oxygen,

hydrogen and carbon:

· Carbon could be sourced from carbon dioxide recovered from the atmosphere using either large scale

extraction facilities or biomass.

· Oxygen would be taken from the atmosphere already contained in the CO2 molecule.

· Hydrogen would be acquired through the electrolysis of water; challenges remain in the electrical

power required; in a green future, this could be supplied from renewable sources, an issue already

being addressed by supporters of hydrogen as a fuel.

Synthetic methanol can also be supplemented by production from biomass sources where properly

sustainable.

· Methanol can be produced easily from a wide variety of feedstocks.

Please see Synthetic Methanol Cycle Diagrams attached

Synthetic methanol – How to make it?

Techniques for the production of synthetic methanol through the extraction of atmospheric CO2 are well

developed and understood but are not being employed on an industrial scale. An early solution would

be the co-location of a nuclear or hydroelectric powerplant with a conventional power station – the

hydrogen generated by hydrolysis of water would be combined with CO2 from either fossil or biomass

sources to make liquid methanol. In the future, large volumes of CO2 could be extracted directly from the

atmosphere.

Synthetic methanol – easy to adopt?

As well as being green, another crucial advantage of synthetic methanol is that it can be introduced

relatively simply. As the Exige 270E Tri-fuel demonstrates, only small changes to engines are required,

such as:

· Sensors to detect alcohol content

· Modified software for engine management control driving alcohol/gasoline, flex fuel and fuel systems

operations.

· Fuel lines compatible with alcohol fuels

· Higher flow rate fuel pump and injectors

· Fuel tank material, compatible with alcohol

In addition, as a liquid, which is miscible with gasoline, synthetic methanol can be transported; stored

and sold to motorists exactly as today's liquid fuels are, with only minor modifications.

Synthetic methanol – a performance fuel?

Synthetic methanol is better suited to spark-ignition combustion than today's liquid fuels, delivering

better performance and thermal efficiencies, due to its higher octane rating giving it better resistance to

'knock'. As a result, it is a fuel that will benefit the motorists in terms of driving experience. For example,

the Exige 270E Tri-fuel is quicker to 60mph from standstill and has a higher top speed when using

100% synthetic methanol fuel than with conventional gasoline. Synthetic methanol is also ideally suited

to pressure-charging, a trend already well underway as car makers look to downsize engines to reduce

fuel consumption.

Synthetic methanol - the way forward

Lotus Engineering regards sustainable alcohols as the third step in a process towards carbon neutral

driving. The current E85 (85% ethanol and 15% gasoline) based movement represents the first stage in

building momentum towards sustainable fuels. The valuable learning from the current bioethanol

vehicles on the market means that synthetic methanol would easily be managed technically and within

the existing transport, storage and distribution infrastructure. The steps towards a synthetic methanol

economy for transportation fuels could be as follows:

1st Generation: there is a handful of current bioethanol models on sale around the world. These cars run

on E85 bioethanol, which is produced from valuable arable crops (food). This is unsustainable in the

short and medium term as global demand for fuel will outstrip the supply available from farmland to the

detriment of food production, but is a necessary step in the evolution of the market.

2nd Generation: the next generation bioethanol fuels will be based on biomass waste, for example crop

stubble, waste vegetable-based oils and any biodegradable waste matter. This is thought also to be

unsustainable in the medium to long term as the required volume of biomass increases beyond that

which can be supplied.

3rd Generation: sustainable alcohols such as synthetic methanol can be introduced due to its miscibility

with ethanol and gasoline. This fuel can be produced from entirely sustainable, readily available inputs,

with an environmentally neutral overall impact.

4th Generation: Direct Methanol Fuel Cells: over the longer term, sustainable alcohols in internal

combustion will facilitate the soft introduction of direct methanol fuel cells as a long term sustainable

future fuel. This will only be possible with pure methanol pumps on the forecourt which internal

combustion engines can bring forward due to their ability to consume a mixture of fuels.

Lotus Engineering strongly believes governments, fuel suppliers and car manufacturers have a key role

to play in the adoption of sustainable alcohols as a future green fuel.

If car manufacturers were incentivised to produce next generation models for introduction over the next

5 to 10 years as flex-fuel vehicles capable of running on any mix of gasoline and bioethanol, there

would be no need for an unfeasible instant global changeover. Late software changes can permit the

introduction of methanol and fortunately, E85 bioethanol and subsequently synthetic methanol can be

introduced gradually to the marketplace, due to their miscibility.

Should fuel suppliers increase the industrial-scale production of synthetic methanol, it could be

introduced to forecourts across the globe within 15-20 years and eventually become a global standard.

The Lotus Exige 270E Tri-fuel

The Lotus philosophy is all about performance through light weight. The Exige 270E Tri-fuel is built to

the lightest specification possible without resorting to expensive and rare materials. The performance

improvements of using synthetic alcohol have been made through increasing the power of the engine

without increasing its weight and therefore the overall weight of the car.

The Engine

The heart of the Exige 270E Tri-fuel is a Roots-type supercharger (with a sealed-for-life internal

mechanism meaning that it does not require the use of the engine's oil) and air to air intercooler

attached to the tried and tested 4-cylinder, 1.8 litre 2ZZ-GE VVTL-i engine. Using a development of the

supercharger and intercooler package from the Exige S, the Exige 270E Tri-fuel has peak power of 270

hp (201 kW / 273 PS) at 8000 rpm, 184 lbft (260 Nm) of torque at 5500 rpm, up by 51 hp (38 kW, 52

PS) or 19% and 25 lbft 45 Nm or 14% over the standard gasoline Exige S. Maximum engine speed is

8000 rpm (8500 rpm transient for up to 2 seconds).

The low carbon number alcohol fuels methanol and ethanol give more power when burned in the engine

than conventional gasoline (petrol) fuel. The performance benefits come largely from the high heats of

vaporization of methanol and ethanol, which give strong charge-cooling effects, and the increased

octane ratings. There are other secondary thermodynamic effects. Methanol's higher heat of

vaporization leads to a slightly higher performance relative to ethanol. All charge air ducting has been

kept as short as possible with large diameter pipes making sure that the bends in these ducts are not

too tight, to the benefit of throttle response and efficiency. The Roots-type Eaton M62 supercharger is

turned by the crankshaft, and has an integral bypass valve for part load operation.

The 2ZZ VVTL-i engine has two cam profiles – a high speed cam and a low speed cam. The seamless

switch point between these two cams is completely variable depending upon driving conditions and

engine load. This gives the Lotus Exige 270E Tri-fuel a smooth and linear surge of power from idle

speeds all the way to the maximum 8500rpm. An electronic drive-by-wire throttle ensures the quickes

engine response possible whilst keeping the emissions as clean and as low as possible, to meet

relevant legislative demands. Six fuel injectors have been fitted to increase fuel flow to the engine at

normal and higher engine speeds and loads.

http://www.midlandslotus.co.uk/forum/uploa..._5Bstaff_5D.zip

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.