Some of these have probably been posted but as I was away on holiday I'm not sure, so here they are anyway:

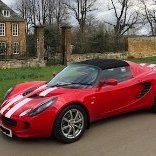

The Lotus 2-Eleven – Track Day Driving Just Got Serious

Exceptional Performance Coupled with High Levels Of Usability and Safety

Geneva, Switzerland (6th March 2007), Lotus Sport, the race car performance arm of Lotus

Cars Ltd, today unveiled the new Lotus 2-Eleven. Launched at the 77th annual Geneva

International Motor Show, the Lotus 2-Eleven is aimed at the true track day enthusiast, taking

Colin Chapman’s philosophy of ‘Performance Through Light Weight’ to its most extreme level

yet.

Weighing in at just 670 kg (1,477 lbs) - dry weight with base specification - 745 kg (1639 lbs) -

kerb weight, fully loaded – and with 255 PS (252 bhp / 188 kw) on tap courtesy of its

supercharged and intercooled 1796 cc engine, the Lotus 2-Eleven boasts a power to weight

ratio similar to that of a 1960’s Formula One car. Designed with the most serious of track day

enthusiasts in mind, the Lotus 2-Eleven offers race car levels of performance coupled with

legendary Lotus Ride and Handling to deliver a truly outstanding track day car.

Said Mike Kimberley, Chief Executive Officer for Group Lotus plc: “The Lotus 2-Eleven takes

our core brand values to the extreme. It is the ultimate track day vehicle - not only

phenomenally quick, but also very user-friendly. In short, the 2-Eleven delivers everything that

the modern track day warrior and clubman racer demands, and more.”

Production of the Lotus 2-Eleven is scheduled to commence in April 2007 at the awardwinning

and world-class Lotus manufacturing facility at Lotus Headquarters in Hethel, Norfolk,

UK. The 2-Eleven build will be completed in dedicated Lotus Sport workshops and each

vehicle will be given a Lotus Sport build plate.

The Lotus 2-Eleven is initially available in Launch Edition specification only, which boasts a

dynamic and unique three-way Lotus Sport colour scheme complete with decal pack. The

Launch Edition is available in two versions - Road Going Version (UK Single Vehicle Approval)

fitted with front and rear lights, exhaust catalyst, single plane rear wing and other items to

achieve compliance with UK road legal requirements and Track Only Version with an

enhanced aerodynamics package including high downforce single plane carbon fibre rear wing, high downforce front splitter, brake lights and rear indicators and FIA approved driver’s

race seat.

The recommended selling price (incl UK VAT) of the Lotus 2-Eleven Launch Edition will be

£39,995. In the UK, the SVA version (Single Vehicle Type Approval) which includes delivery,

Pre Delivery Inspection, first service, number plates, first registration fee, valet, 12 months’

Road Fund Licence, a full tank of fuel and SVA test costs an additional £1,100. The Lotus 2-

Eleven is only available as a track-only option outside of the UK at 49,575 excluding local tax

in mainland Europe. Pricing in Japan, South Africa and Lotus other international markets will

be announced shortly.

The Lotus 2-Eleven in more detail

Engine

The supercharged and intercooled 1796 cc engine in the Lotus 2-Eleven has a maximum

power output of 255 PS (252 bhp / 188 kw) at 8000 rpm and a torque figure of approximately

242 Nm (179 lb/ft) at 7000 rpm. This significant amount of extra power and torque now

available together with the VVTL-i variable cam system ensures that there is a smooth and

linear surge of power from low engine speeds all the way to the maximum 8000 rpm. The

Roots-type Eaton M62 supercharger (with a sealed-for-life internal mechanism meaning that it

does not require the use of the engine’s oil) is run from the crankshaft and has an integral

bypass valve for part load operation. Four high capacity injectors and an up rated fuel pump

add additional fuel under hard acceleration or high speed driving.

An Accusump (engine oil accumulator unit) is included in the whole package as an oil reservoir

back-up for extreme track use ensuring that, under those conditions, the engine oil pressure

remains constant.

Twin oil coolers complete the powertrain package. Transmission

A sports-type clutch plate and heavy duty clutch cover transfer the engine power and torque to

the lightweight aluminium C64 six-speed gearbox (with an aluminium casing) – with the same

perfectly spaced ratios as the Exige S. An open type differential is fitted as standard. The

Lotus switchable Traction Control System (LTCS) works through the engine, reducing power

to maintain traction; it is active above 8 km/h (5 mph) and reacts much more quickly than

many brake-based systems.

Chassis & Integral Safety Features

The Lotus 2-Eleven uses a unique high-sided variant of the Lotus Elise lightweight chassis

structure featuring epoxy bonded aluminium alloy extrusions with modified Exige S based

running gear. This strong and stiff package features a comprehensive safety system with a

glass fibre reinforced composite front crash structure allied to a high sill chassis for side impact

protection. Additional chassis safety features include an FIA compliant 6-point rollover

structure with integral harness mounts and lightweight rear sub frame incorporating a further

crushable structure.

Body

The Lotus 2-Eleven features all new ultra-lightweight (40 kg / 88 lbs) composite bodywork

featuring core-mat technology. All external panels are bolted on for ease of removal,

maintenance and repair.

Wheels & Tyres

5-spoke lightweight forged black alloy wheels (front 7Jx16, rear 8J x 17) are shod with Lotus

Sport specific Yokohama A048 R LTS tyres (front 195/50 R16, rear 225/45 R17), designed to

maximise grip and achieve the exacting ride and handling targets set by Lotus. Brakes

The brake system includes 288 mm cast iron cross drilled and ventilated discs, upgraded

Pagid RS14 sports brake pads set into the brake calipers (aluminium alloy AP Racing 2-piston

at the front and Brembo single sliding piston at the rear), high grade silicone brake fluid and

stainless steel braided hoses. In addition, the proven Lotus track tuned servo-assisted fourchannel

ABS system enhances braking performance and minimises stopping distance without

taking over from the skill of the driver.

Suspension

Fully independent suspension utilising unequal length wishbones; Öhlins 2-way adjustable

dampers with coil over springs and Lotus Sport adjustable front anti-roll bar. A rear double

shear track control arm brace is provided to cope with the expected kerb abuse during heavy

track day driving, with unique steering arms and front upper wishbones to suit ultra-low ride

height.

Performance

0-60 mph 3.8 secs (estimated)

0-100 km/h 3.9 secs (estimated)

0-160 km/h (0-100 mph) 9.1 secs (estimated)

Max Speed 155 mph (250 km/h)

Max Power 255 PS (252 bhp / 188 kw) at 8000 rpm

Max Torque 242 Nm (179 lb/ft) at 7000 rpm

http://www.midlandslotus.co.uk/forum/uploa...pr_download.pdf

http://www.midlandslotus.co.uk/forum/uploa...pr_download.pdf

‘EVE HYBRID’ TECHNOLOGY DEMONSTRATOR SHOWCASES

RETRO-INTEGRATION OF HYBRID SOLUTIONS

An Innovative R & D project by Lotus Engineering and Proton Holdings Bhd features

hybrid solutions that deliver up to 22% CO2 reduction and are advancing towards

readiness for integration into current models.

Lotus Engineering will unveil the ‘EVE Hybrid’ (Efficient, Viable, Environmental) technology

demonstrator at the 77th Geneva International Motor Show. Developed for, and in close R & D

Engineering cooperation with, our shareholder, Proton Holdings Bhd, it showcases how OEMs

can introduce lower emissions variants to existing model ranges that currently only offer

conventional gasoline and diesel powertrains.

Lotus Engineering believes the application of hybrid technology is a key route for CO2

emissions reduction and that for the next five years it may remain more viable to integrate

hybrid technologies into existing model ranges than to develop expensive new dedicated

hybrid platforms. Solutions that Lotus Engineering can provide to its OEM clients will help

them keep price premiums for hybrid variants at a minimum, thanks to lower development

costs, and are available immediately for introduction within current and next generation model

lifecycles.

The EVE Hybrid programme is focussed on establishing the processes for integrating hybrid

technology with minimal development time and cost, overcoming many of the challenges

associated with integrating hybrid technology into existing platforms through intelligent,

compact and discreet packaging of additional systems.

Ultimately, Lotus Engineering’s solutions aim to provide strong, viable business case

propositions for our OEM clients to offer a hybrid variant of a medium-high volume production

car.

The research and development programme was undertaken by a cross-functional team of

Lotus and Proton engineers working seamlessly together at Lotus Engineering’s Hethel

headquarters and Shah Alam, Kuala Lumpur. The resulting EVE Hybrid demonstrator, based

on a Proton Gen.2 compact midsize car with a 1.6litre gasoline engine, showcases a trio of

production-representative technologies:

(1) a ‘micro-hybrid’ start-stop system

(2) a full parallel hybrid drive

(3) Continuously Variable Transmission

Compared to the baseline Proton Gen.2, tailpipe emissions are reduced from a competitive

172g/km to just 134g/km, a reduction of 22%, while fuel economy improves from 39.2mpg to

50.2mpg, a 28% improvement.

Mike Kimberley, Chief Executive Officer of Group Lotus plc, said: “The technologies and knowhow

showcased in the EVE Hybrid are the latest addition to our suite of efficient performance

solutions for the industry. As an automotive consultancy and Global OEM, Lotus is able to

manage all elements of a hybrid integration project under one roof, with extensive drivetrain,

vehicle, electrical and control systems expertise from design and development through to

production. Our technologies and world-class engineering capabilities mean we are in a great

position to help OEMs apply advanced hybrid technology to their products in order to reduce

average CO2 emissions.”

Mr Kimberley continued: “This project is yet another example of how the Proton / Lotus family

continues to successfully deliver exceptional projects and products and the EVE Hybrid

technology we have developed further reinforces the Group’s position as creative technology

leaders in ‘green’ automotive engineering. The addition of the EVE Hybrid solutions to Lotus

Engineering’s extensive capabilities, together with the experience of developing our Bio

Ethanol flex-fuel Lotus Exige 265E means that Lotus Engineering is an ideally placed high

Technology organisation suited to helping the global industry to find a solution for future low

emission personal transport needs.”

Technologies in the EVE Hybrid technology demonstrator

A number of the technologies featured in the EVE Hybrid are production-ready, employing

systems deliberately sourced from established tier one suppliers in order to demonstrate the

availability of components, the minimisation of development costs and to maximise business

case viability.

The EVE Hybrid features three key technologies:

(1) ‘Micro-hybrid’ stop-start system:

A starter-alternator system was integrated that switches the engine off when the vehicle stops,

during town driving for example. The engine restarts automatically when the brake pedal is

released.

As a result, noise, emissions and fuel consumption are reduced. The unit runs on the standard

vehicle 12volt electrical system and combines both starter motor and alternator functionality.

Fuel savings of 5% have been demonstrated with a 5% reduction in CO2 emissions.

(2) Full parallel hybrid technology:

A bespoke 30kW, 144V motor is packaged between the engine and transmission. It delivers

electric drive or regenerative braking via an additional clutch linking the motor to the drivetrain.

The motor provides the same start-stop functionality as the micro-hybrid with the additional

benefit of electrical drive or drive assist, either boosting the drivetrain performance or providing

economy and emissions benefits by operating as an electric vehicle. The motor is powered by

a 144 volt battery located in the boot.

Testing has confirmed simulation predictions of 28% fuel efficiency improvement and 22% CO2

emissions reduction.

(3) Continuously Variable Transmission (CVT)

The CVT is a transmission in which the ratio between the input and output shaft can be varied

continuously within a given range, providing an infinite number of possible ratios. The

integration of a CVT gives benefits in fuel consumption and emissions control. In addition, its

compact package assisted in the application of a hybrid electric drive and it provides smooth

acceleration and low transmission noise.

Performance benefits of EVE Hybrid technologies

Extensive performance and drive cycle modelling of a production hybrid variant using the

technologies on the EVE Hybrid indicate the following comparative vehicle performance

figures:

(1) EVE Hybrid in micro-hybrid mode with start-stop system:

MPG: 41 (5% increase from baseline)

Max torque: 148Nm @ 4000rpm

Max power: 82kW / 110hp @ 6000rpm

0-62 mph (0-100kph): 12.6 sec

Top speed: 118mph

CO2: 164g/km (5% reduction from baseline)

(2) EVE Hybrid with full parallel hybrid configuration:

MPG: 50.2 (28% increase from baseline)

Max torque: 233Nm (limited to180Nm continuous) @ 1500rpm

Max power: 105kW / 141hp @ 5500rpm

0-62 mph: 9 sec

Top speed: 118mph

CO2: 134g/km (22% reduction from baseline)

(3) Continuously Variable Transmission configuration

MPG (EU combined cycle): 41 (5% increase from baseline)

Max torque: 148Nm @ 4000rpm

Max power: 82kW / 110hp @ 6000rpm

0-62 mph (0-100kph): 12.6 sec

Top speed: 118mph

CO2 (combined cycle): 164g/km (5% reduction from baseline)

Proton Gen.2 1.6litre 4-cyl gasoline (manual transmission) baseline for comparison:

MPG (EU combined cycle): 39.2

Max torque: 148Nm @ 4000rpm

Max power: 82kW / 110hp @ 6000rpm

0-62 mph (0-100kph): 12.6 sec

Top speed: 118mph

CO2 (combined cycle): 172g/km

Technical details of EVE Hybrid technology demonstrator

Engine

Various changes have been made to the Proton gasoline 1597cc CamPro engine. The main

modification is the redesign of the front end accessory drive (FEAD). This was done to

accommodate a Valeo ‘StARS’ starter/alternator, which drives the micro hybrid start-stop

system.

The redesigned FEAD also accommodates a Sanden hybrid Heating Ventilation and Air

Conditioning (HVAC) compressor that operates by conventional belt drive and has an

additional electrically driven capability which enables continued air conditioning operation

when the engine is stopped.

During the FEAD redesign the opportunity was also taken to replace the belt driven Power

Assisted Steering (PAS) and water pumps with electric units to enable the investigation into

the economy benefits of such units.

To accommodate the additional hybrid functionalities the Engine Management System (EMS)

was updated to a Siemens VDO torque-based unit and re-calibrated by Lotus Engineering.

Motor/Generator

Due to tight packaging constraints and to minimise any loss in overall vehicle performance,

bespoke electric motor and power electronics were developed in conjunction with specialist

suppliers ElektroMagnetix and Turbopower Systems. The motor/generator and power

electronics are water-cooled and include an auxiliary power unit to support the vehicle’s 12volt

systems.

An additional clutch supplied by AP Racing is packaged inside the motor and connects the IC

engine to the traction motor. This enables the engine to be switched off for electric drive only

use.

Gearbox

A Punch Continuously Variable Transmission (CVT) has replaced the conventional

transmission and a modified bell housing accommodates the electric traction motor.

Battery Pack

The EVE Hybrid uses a Cobasys Series 1000, NiMH, 30kW 144V module that incorporates an

integrated cooling system. This traction battery pack is securely mounted on the boot floor,

displacing approx 47 litres of luggage space.

Control System

A sophisticated bespoke Lotus Engineering control system was developed to implement the

energy management function by monitoring and controlling all sub-control systems including

the engine management, motor/generator, transmission, HVAC, additional clutch,

starter/alternator and battery pack.

Brake System

To maintain the integrity of the braking circuit when the petrol engine is off, a Mes-Dea electric

vacuum pump maintains the vacuum assist for the brakes.

Steering System

An off-the-shelf TRW electro-hydraulic power assisted steering pump has been fitted, which

allowed the retention of the existing steering column and hydraulic steering gear. This pump

also provides hydraulic pressure for the additional clutch that engages the hybrid motor.

Interior

The instrument panel incorporates an additional LCD display developed by Lotus Engineering

to show battery charge, power split between engine and motor, fuel economy and

charge/discharge rate, and incorporates associated warning indicators where appropriate.

Also fitted to the dash are new switches to select the car’s operating mode - micro hybrid, full

hybrid or electric vehicle.

http://www.midlandslotus.co.uk/forum/uploa...pr_download.pdf

Lotus Launches the Exige GT3 Concept Road Vehicle

UNLEASHED! The Most Extreme Exige Variant To-date

Geneva, Switzerland (6th March 2007), Lotus Sport, the race car performance arm of Lotus

Cars Ltd, today unveiled the Lotus Exige GT3 concept road vehicle. With its debut at the 77th

annual Geneva International Motor Show, the 275 PS (271 bhp / 203 kW) Exige GT3 is a bold,

no-holds-barred, lap record-breaking, breathtaking performance machine that embraces all

that is expected of a race-bred Lotus.

Building on the Lotus racing pedigree, this concept car can deliver more grin-factor than ever

before; there are no intended compromises and no limits except those that are self imposed by

the driver.

This is one concept that commands your full attention.

Said Mike Kimberley, Chief Executive Officer for Group Lotus plc:

“The Exige GT3 concept road car is a fantastic showcase product from our race car

performance division, Lotus Sport. The car’s racing background becomes immediately

obvious from its aggressive stance, extreme width of rear track and innovative threedimensional

rear wing. The foundation of all Lotus products is phenomenal handling and ride

characteristics, but the Exige GT3 takes these into another dimension altogether where

supreme road holding and outrageous acceleration come evenly matched with sensational

stopping ability.”

The Exige GT3’s pure bred racing brother will be again competing in the GT race arena in

2007, taking over the mantle from the hugely successful 2006 British GT3 Championshipwinning

car. On road or track the Lotus Exige GT3 winning pedigree will continue in time

honoured Lotus racing tradition.

A new one-piece front clam-shell with fully masked front wheels and wheel arch venting leads

the aerodynamically cleaned silhouette of this car. A menacing stance is enhanced by the

aggressively flared rear wheel arches and aero-efficient three-dimensional rear wing and

blended end-plates. The visual message is clear; this vehicle means business and the squat

wide hindquarters symbolise the latent power harnessed within.

That power is provided by the same charge-cooled supercharged engine that the GT3 race car

employs, producing 275PS (271bhp / 203kw) driven through ten inch rear wheels with 255

width tyres making the final connection to the road. Max speed (257kph / 160mph) and peak

torque have been electronically limited but acceleration is left untouched and unimpaired. The

up-rated front brakes and brake pads all round ensure that on road or track this car’s stopping

ability is more than capable of harnessing its acceleration performance.

The end-plate mounted three-dimensional rear wing is highly efficient and fully complements

the widened and flattened rear deck shape in reducing the overall drag as well as maintaining

front to rear downforce balance. The performance of this car will amaze and reward all drivers

with incredible road holding (developed with the help of its 2-way Ohlins adjustable dampers

together with Lotus Sport adjustable front stabiliser bar and rear suspension double-shear

track control arms) and stunning acceleration.

Simply put, the Lotus Exige GT3 will redefine your concept of a road car by re-affirming that

unique proposition that is, above all else, a Lotus.

It is intended that the Lotus Exige GT3 concept road vehicle will be further developed into a full

production car for limited markets, to go on sale in late 2007 with an estimated price tag of

between £50,000 and £60,000.

The Lotus GT3 in more detail

Engine

The supercharged and chargecooled 1796 cc engine in the Lotus GT3 has a maximum power

output of 275 PS (271 bhp / 203 kw) at 8000 rpm and a torque figure of approximately 258 Nm

(190 lb/ft) at 7000 rpm. This significant amount of extra power and torque now available

together with the VVTL-i variable cam system ensures that there is a smooth and linear surge

of power from low engine speeds all the way to the maximum 8000 rpm. The Roots-type

Eaton M62 supercharger (with a sealed-for-life internal mechanism meaning that it does not

require the use of the engine’s oil) is run from the crankshaft and has an integral bypass valve

for part load operation. Four high capacity injectors and an up rated fuel pump add additional

fuel under hard acceleration or high speed driving.

An Accusump (engine oil accumulator unit) is included in the whole package as an oil reservoir

back-up for extreme track use ensuring that, under those conditions, the engine oil pressure

remains constant.

Twin oil coolers complete the powertrain package.

Transmission

A sports-type clutch plate and heavy duty clutch cover transfer the engine power and torque to

the lightweight aluminium C64 six-speed gearbox – with the same perfectly spaced ratios as

the Exige S. An open type limited slip differential is fitted as standard. The Lotus switchable

traction control system (LTCS) works through the engine, reducing power to maintain traction;

it is active above 8 kph (5 mph) and reacts much more quickly than many brake-based

systems.

Chassis Structure

Lotus designed lightweight structure of epoxy bonded aluminium alloy extrusions with crash

structure, extruded aluminium door beams, integral steel seat-belt support structure and

lightweight galvanized steel rear sub frame incorporating a structural shear panel.

Body

GT3 derived one-piece front clamshell and wide track rear clamshell with full length roof scoop

design taken from the Cup Exige 255. New full width rear wing with integral end plates

mounting to rear clam. Race style full width front splitter; standard Exige door and body sides

retained. Multi element rear diffuser with carbon option.

Wheels & Tyres

5--spoke lightweight forged alloy wheels (front 7Jx16 and rear 10Jx17) are shod with Lotus

Sport specific Yokohama A048 R LTS tyres (front 195/50 R16 and rear 255/40 R17), designed

to maximise grip and achieve the ride and handling targets set by Lotus.

Brakes

The brake system includes 308 mm diameter 2 piece aluminium belled cross drilled and

ventilated front discs and 288 mm diameter cross-drilled and ventilated rear discs. AP Racing

two-piece radially mounted 4 piston calipers at the front and Brembo single sliding piston at

the rear. Pagid RS14 sports brake pads all round. High grade silicone brake fluid; stainless

steel braided brake hoses. In addition, the proven Lotus track tuned servo-assisted fourchannel

ABS system enhances braking performance and minimises stopping distance without

taking over from the skill of the driver.

Suspension

Fully independent suspension utilising unequal length wishbones; Öhlins 2-way adjustable

dampers with coil over springs and Lotus Sport adjustable front anti-roll bar. A rear double

shear track control arm brace is provided to cope with the expected kerb abuse during heavy

track day driving.

Performance

0-60 mph 3.9 secs (estimated)

0-100 km/h 4.0 secs (estimated)

0-100 mph 9.8 secs (estimated)

(0-160 km/h)

Maximum Speed 160 mph (257 km/h) - electronically limited

Max Power 275 PS (271 bhp / 203 kw) at 8000 rpm

Max Torque 258 Nm (190 lb/ft) at 7000 rpm (electronically limited)

http://www.midlandslotus.co.uk/forum/uploa...pr_download.pdf

http://www.midlandslotus.co.uk/forum/uploa...pr_download.pdf

Lotus Engineering launches ‘Integrated Exhaust Manifold’ Design Capability

Cuts Cost, Emissions and Weight

Lotus Engineering will showcase a highly advanced cylinder head with integrated exhaust

manifold (IEM) at the 77th Geneva International Motor Show. The production-ready technology

can significantly reduce manufacturing costs, emissions and weight on most gasoline-engined

passenger vehicles.

The cylinder head on display, for a small 3-cylinder engine, is the latest of a number of IEM

designs developed by Lotus Engineering as part of its world-renowned consultancy business.

Following its development programmes, the UK automotive engineering consultancy estimates

that for a typical DOHC 16-valve 1.6 cylinder gasoline engine, an IEM has potential to:

· cut up to 5% of the total build cost

· reduce catalyst light-off time by up to 20% (approx five seconds)

· reduce powertrain mass by up to 5 kg

· improve engine durability

Geraint Castleton-White, head of powertrain, Lotus Engineering said: “Two key drivers for

OEM’s are cost-down and the reduction of CO2 emissions. Our IEM technology brings to a

practical reality an established principle that has been very challenging to implement in

production. Over a series of design projects, we have developed a proven expertise in the

application of IEM designs, and we can now deliver the significant benefits of this technology

to our clients.”

Mike Kimberley, Chief Executive of Group Lotus plc, said: “Efficient performance is a core

focus of Lotus Engineering and we are working on many ways to drive down CO2 emissions.

With our numerous on-going bio-fuel, Hybrid and electric vehicle projects based on Lotus’

fundamentally ecologically-designed products using all-aluminium low weight structures for

exceptional fuel economy with extreme driving pleasure, we are continually reinforcing our

position as world leaders in ‘green’ automotive engineering.”

By integrating the manifold tracts into the cylinder head the parts count is reduced significantly,

saving costs throughout the development cycle and supply chain, from inventory and

assembly to aftermarket supply.

Emissions reduction is achieved by locating the catalyst very close to the cylinder head which

reduces exhaust gas heat loss upstream thereby cutting the catalyst light-off time. The

reduction in overall engine heat loss is achieved through minimising the surface area of the

manifold by keeping the exhaust tracts within the head. Through intelligent cooling jacket

design, heat is retained in the engine rather than lost to the engine bay, accelerating engine

warm-up so it more quickly reaches optimal efficiency. This also benefits the HVAC

performance, reducing windscreen demist and passenger cabin warm-up periods.

Engine durability is improved as a result of the reduction of thermal stresses in the engine.

With the exhaust manifold integrated into the cylinder head, the stresses usually associated at

the interface of different materials, for example where the cast iron exhaust and the aluminium

cylinder head meet in a conventional design, are eliminated. Also, due to the design of the

cooling jacket and coolant routing, the coolant heats up far quicker, resulting in a more uniform

heating of the entire engine, again contributing to reduced stresses in the engine.

Integrating the exhaust manifold reduces the mass of the engine, further increasing overall

vehicle efficiency. It also results in a more compact overall engine and reduced packaging

demands for the engine under the hood, delivering a range of subsequent benefits for vehicle

packaging.

Lotus Engineering has already proved the concept to production readiness in several

demonstrator programmes with a variety of cylinder head configurations.

Detailed benefits:

· Ultra-low CO2 emissions with reduced cost

o Reduction in emissions through faster light-off of close-couple catalytic converter

o Reduced BOM and assembly cost

o Reduced catalyst loading requirement

· Vehicle integration benefits

o Reduced overall weight

o Reduced package space requirements

o Improved underhood thermal management

o Faster cabin heater warm-up

o Higher vehicle integration flexibility

o Improved NVH

· Additional benefits

o Reduced windscreen demist time

o Reduced thermal distortion

o Improved overall engine durability

http://www.midlandslotus.co.uk/forum/uploa...pr_download.pdf

Luxury Touring Pack Option for Lotus Europa S

More Choice for the Discerning Lotus Driver

The Europa S, the Lotus that introduces the brand to enhanced levels of practicality and

refinement, has a new Luxury Touring Pack Option which stretches the Europa S towards the

more luxurious end of the spectrum.

The Luxury Touring Pack Option dresses the interior in the smart attire of saddle tan leather,

chocolate coloured leather and brown carpets. Where the standard Europa S uses lightweight

composite components for items such as the steering column shroud, dash top, instrument

and ventilation binnacles and sill covers, the Luxury Touring Pack Option on the Europa S

covers these and other components with four hides of soft high-grade saddle tan coloured and

chocolate coloured leather. Supportive sports seats are fitted and are also clad in saddle tan

and chocolate coloured leather in a stripe pattern. Safety critical composite components such

as the passenger airbag door are coated in a high-tech soft-to-the-touch material. An engine

start button and a solid Walnut and Tulip wood gearknob finish off the interior package.

The Luxury Touring Pack Option also stretches to the boot: with brown carpet covering the

whole of the boot area including the battery cover, a saddle tan coloured leather trimmed

tailgate inner, luggage straps to prevent luggage from moving in the boot (Lotus still expects a

laden Europa S to be driven hard!), and a saddle tan coloured leather oddment bag which is

fixed to the boot compartment.

Exterior additions to the Luxury Touring Pack Option include tinted rear and rear three-quarter

glass, body coloured front driving lamp surrounds, side air-intake surrounds and roof air-outlet

grill. All other exterior grilles such as the front radiator grilles and the rear light grille surrounds

are coloured silver.

All these added luxuries add very little weight to the feather-light Europa S so spirited drivers

will not be penalised by opting for the Luxury Touring Pack.

Availability

The Luxury Touring Pack Option is available on the Lotus Europa S from April 2007 priced at

£1,250 in the UK and 1,750 in Europe (excluding local taxes), with prices in other markets to

be announced shortly.

http://www.midlandslotus.co.uk/forum/uploa...pr_download.pdf

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.