Went to Hethel yesterday with some chaps on here to attend the factory tour in the pm and the Classic Team Lotus tour in the evening. A great day so I thought I'd post up my experiences for others. I realise this is VERY long so I'll do the Classic Team Lotus one seperate. Sorry if I go on a bit. Arrived at Hethel, deposited all cameras at the gate and went into reception to start the tour. We were taken round by the Manufacturing Supervisor, Colin (not Chapman but can't remember his second name). A very knowledgeable chap who obviously was proud of the work his team did.

You enter the factory at the end of the production line but we made our way through to the start before the tour proper began. First impressions: it's a lot smaller than I was expecting and there is a distinct lack of heavy machinery.

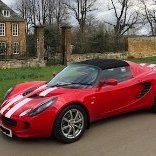

We start at the bodyshop. Elise panels are made in France so they are brought in more or less ready to be painted. They're readily identifiable as they are a pristine white colour. Exige clams are still made the "old-fashioned" way and are made in-house by hand. These are powder blue.

We saw the training mule for the Europa clams and panels. Much is made of the shortened sills but it doesn't look that lower to me. There was an empty coffee cup in one of the horizontal chassis members so if anyone buys one and there is a mystery rattle.....

We see the body panels being moved into the paint booth. They are transported on a trolley that allows the panels to be held in their finishing position.

However, the Sports Racer model and other models with stripes are actually assembled on a chassis in order to get the lines measured up exactly. Colin mentioned that this new level of detail is all due to the GM quality processes they had to adopt to build the VX220. Pre-VX220 Elises didn't have this level of work put into them and some of the cars had some interesting stripes.

There is a myriad of painted panels and clams around us (at the start of the tour we're asked to remove rings, etc to protect the paintwork). There's actually a lot of white cars that are destined for Japan. These are being built with the remaining K-series.

Onto the production lines (there's currently 2 running - 1 for federal Elises/Exiges, one for RHD). Starting point is the chassis and it moves through defined stages for wiring, electric, suspension, engine, crash structure, etc, etc. As the car gets heavier it is moved through a series of hand operated cranes. To be honest, this is the part that looks very monotonous.

Each stage is controlled by a computer that controls the torque settings for the power tools. If it hadn't been assembled correctly the computer wouldn't allow the car to move to the next stage. Important part numbers, etc and details about who carried out a job are stored by the computer and on a log book that follows the car through the process.

After every 5 steps in the build there is a quality sign off process.

Panels are assembled and fitted to the car using a jig. Geometry setting were then completed. Windscreen is added and then the interior components. Then fluids are added.

There was a real mix of cars here, some that obviously were "special order". A lightning yellow Exige S with Ohlins destined for France springs to mind.

Moving to the next area, 10 litres of petrol added and the engine is started for the first time. Electrics are also checked. Stored in this corner was the Europa test mule (the version that appeared in all the mags). It was being disassembled and Colin mentioned that it had probably done 40,000 miles. The interior had been stripped but we did get a close look at the rest. In my opinion, it's ok but just not different enough.

We move through to the final part of the factory where the cars have their final inspections and any issues are fixed (a spray booth is also in here to fix any paint issues). There's a variety of Elises and Exiges all waiting for final sign off.

First thing is a quick rolling road session that measures braking capability as well as power. It also gives the engineer the change to make sure all the warning lights and exterior lights are working.

Then the undertrays are fitted.

Just as well, as the next stop is the water testing booth. The car is driven into the booth where water is sprayed at 80psi at the car from 8-9 directions (including underneath). The engineer checks for leaks and the test can take as long as 2 3/4 minutes. My S1 Exige would be lucky to last 2 3/4 seconds in there so, again, another step forward in quality.

Final step is a very detailed paint and interior check and a thorough polish and it's moved outside to brave the Norfolk weather to wait to be loaded onto a transporter.

Outside there's a krypton green Exige and a Honda Accord thraping round the test track. Looks fun but we're not allowed to join in.

As we walk back to reception we spot a heavily disguised Europa with the S2 Exige spoiler added driving by. Another version or a binned idea?

Also spotted Gav Kershaw leaving in a laser blue 55 reg Exige S and quite a few Europa mules further down the front car park. Shame cameras aren't allowed but that is understandable.

Final impressions:

I'm impressed by the importance of quality. I'm not as keen on the VX220 but it seems it's production at Hethel really helped them focus on producing a really well put together car.

The production line was a lot more "hand-crafted" than I expected. I suppose this is all due to the way the Elise is built as it can be more or less moved by hand so easily.

Definitely a good day out and for £20 was good value. There's also an opportunity to buy some tat in the shop at the end.

I would recommend you do it in conjunction with a Classic Team Lotus evening and more on this in a minute....

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.